Paul came over today to have a sneaky peak at his bike ............. time for an update!

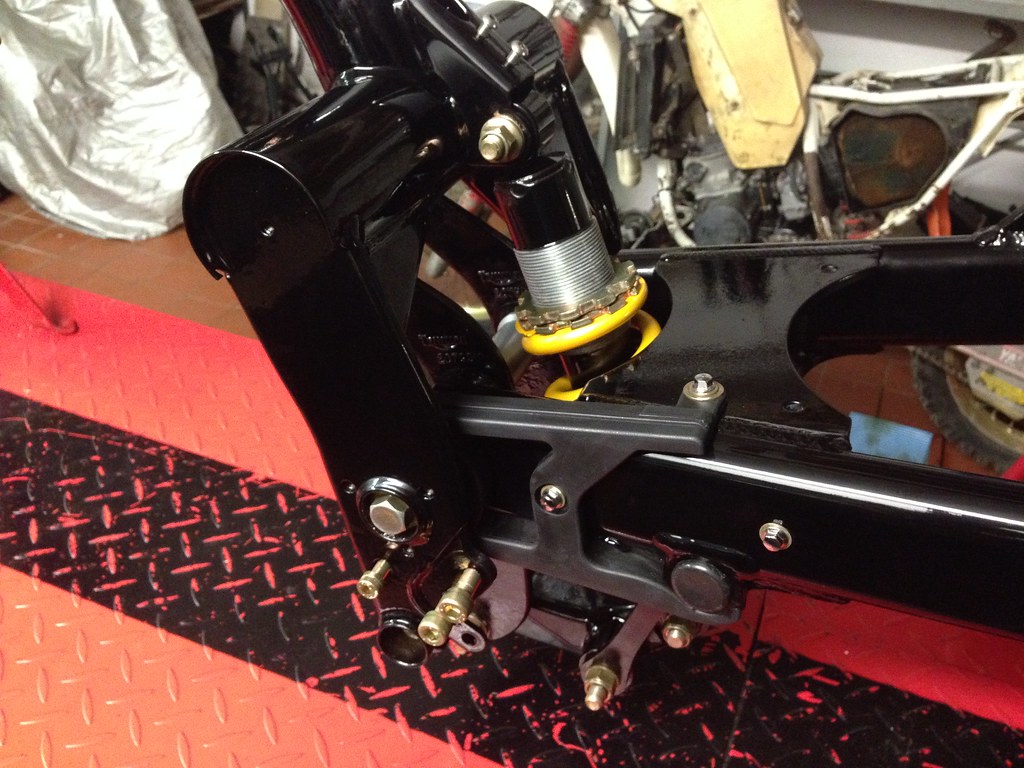

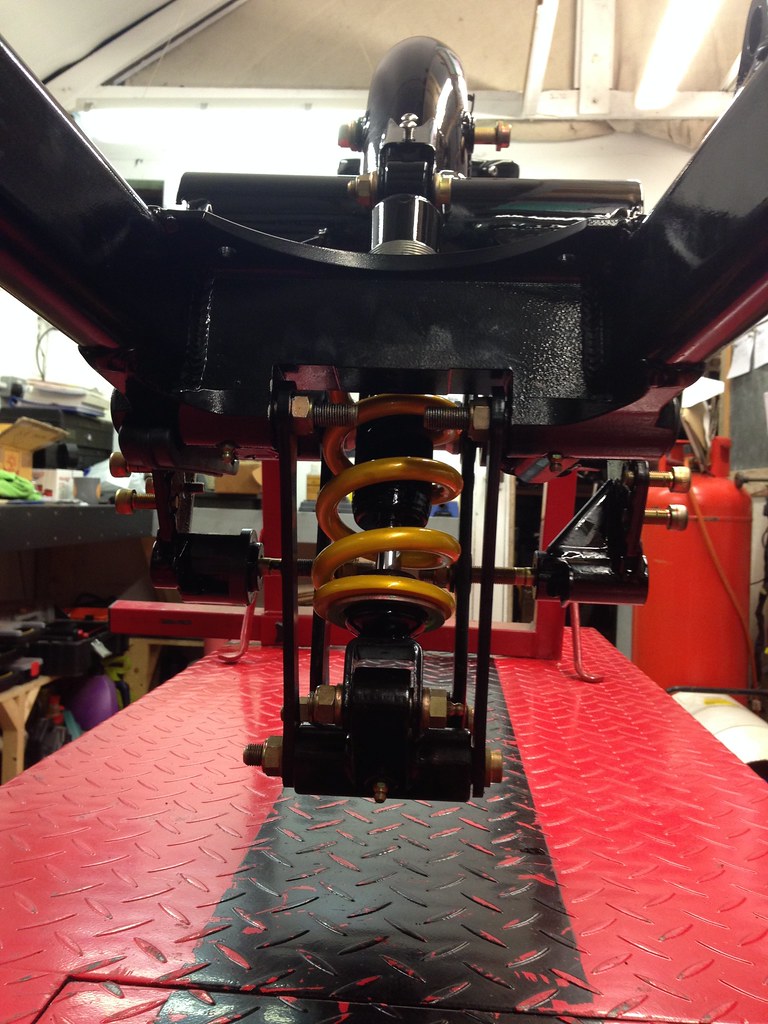

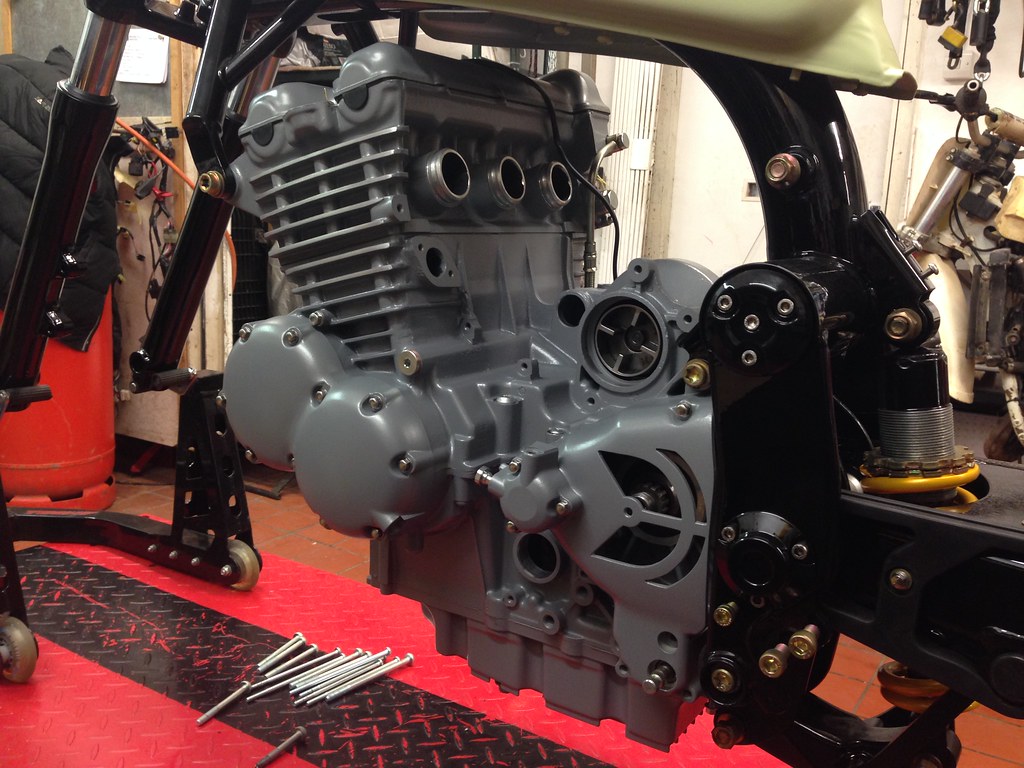

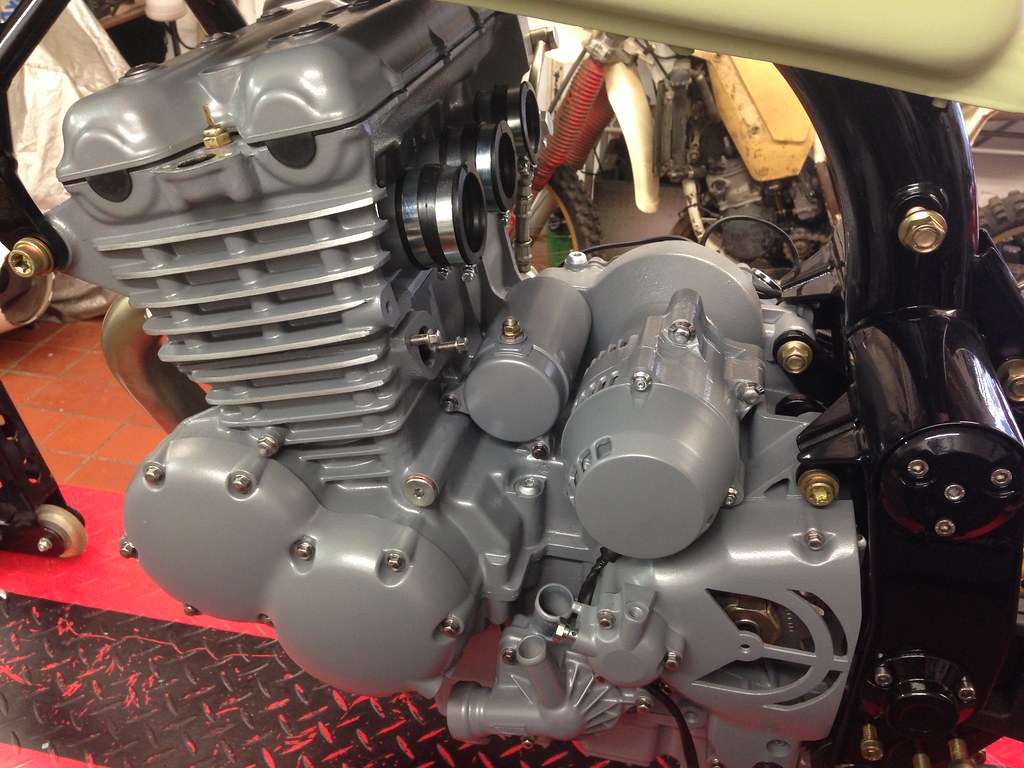

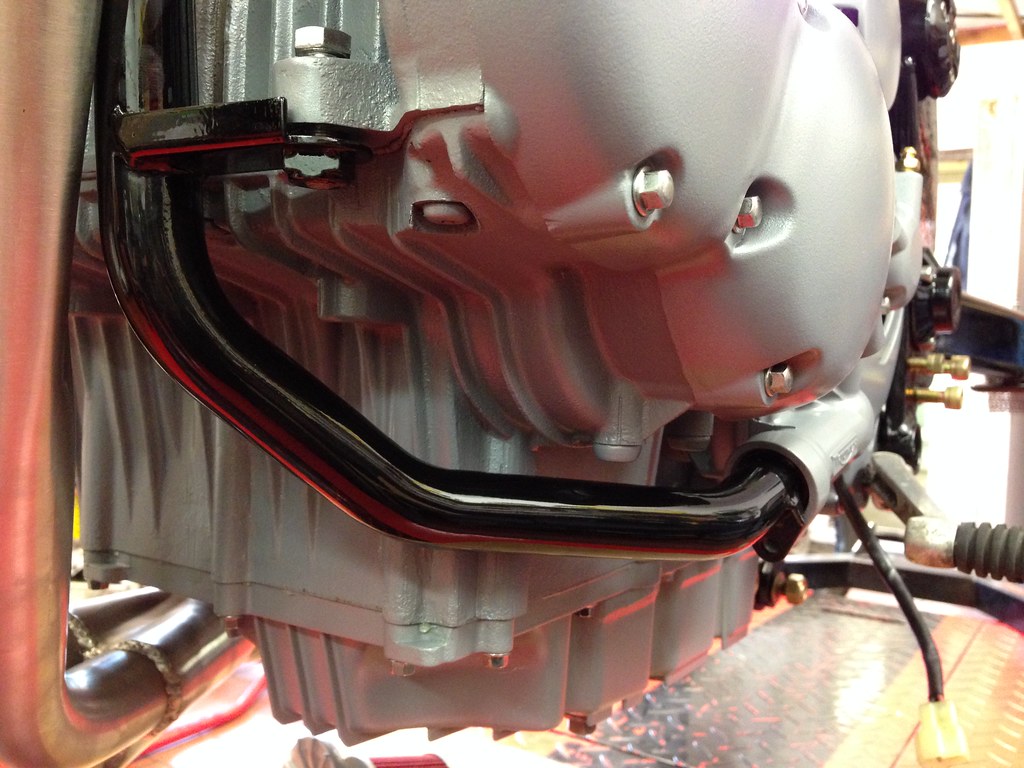

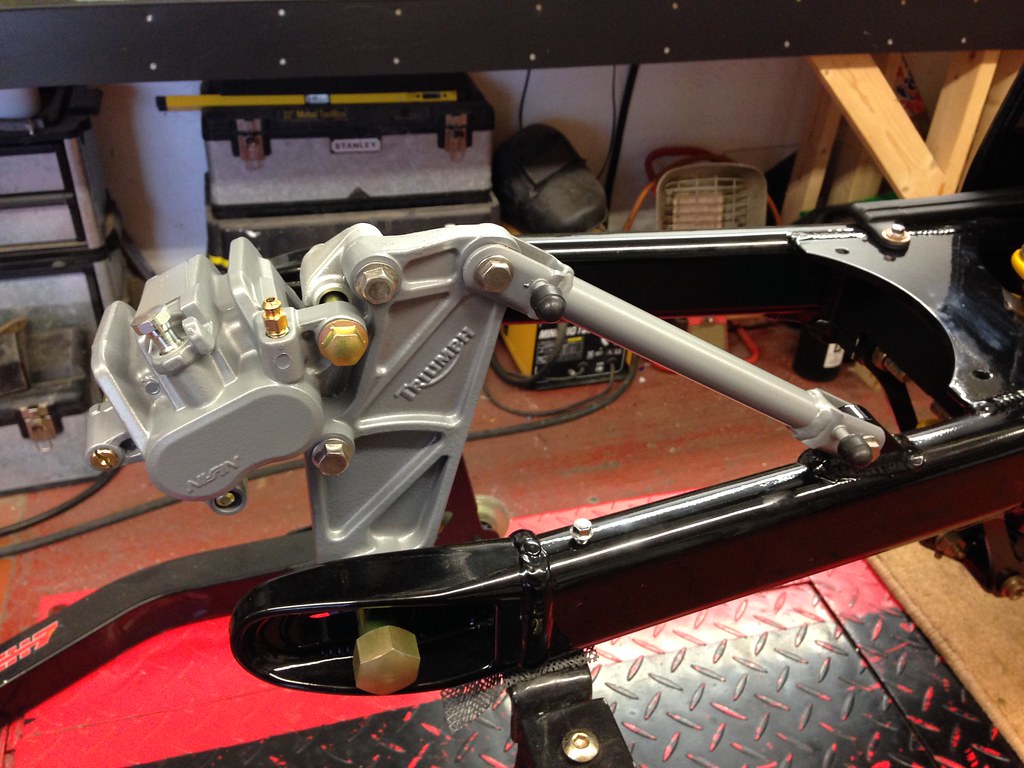

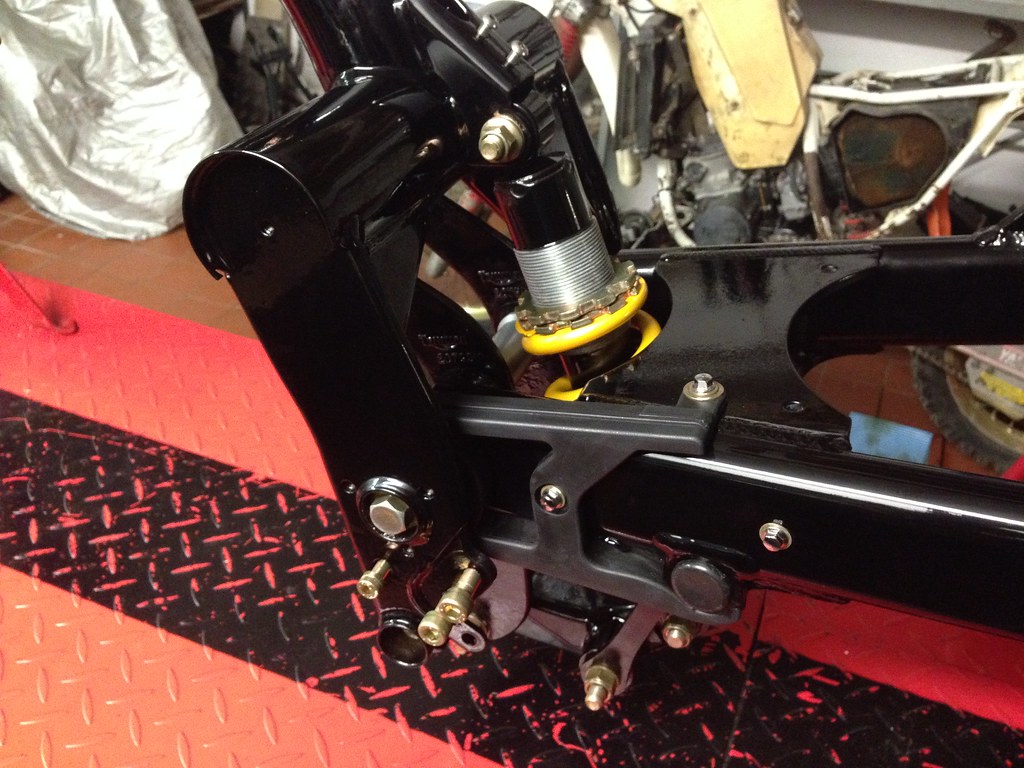

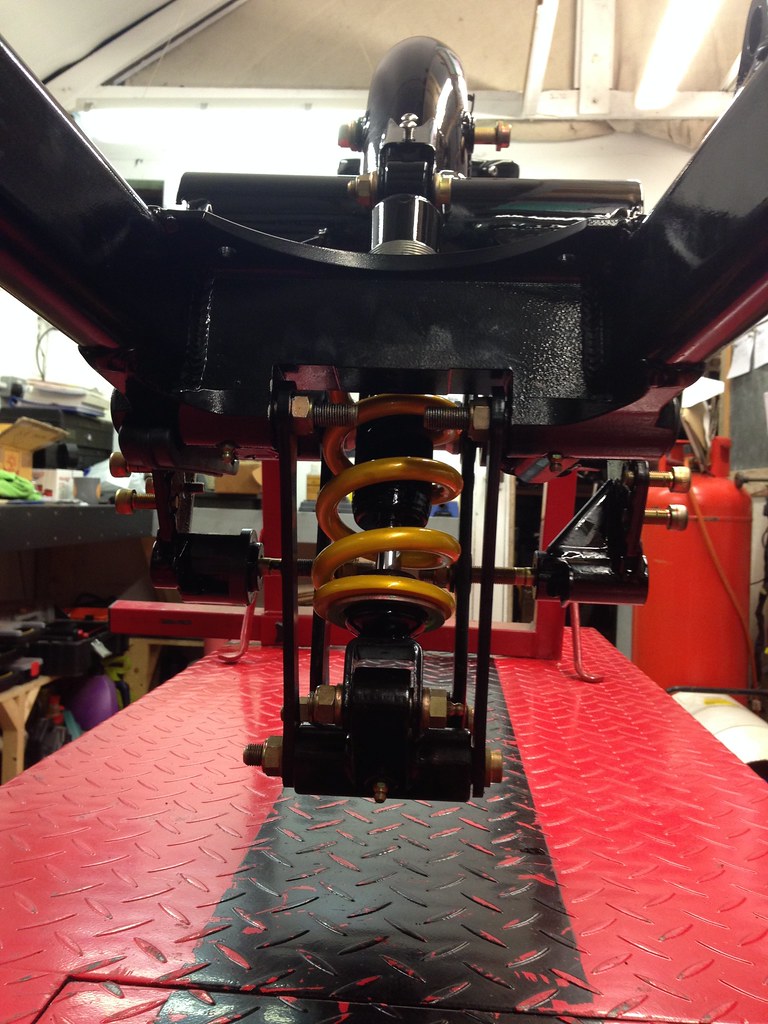

Having finally baked off all the parts that make up the suspended chassis it was time for some assembly.

Anyone thats done a project like this will know that initially there a huge surge of activity and excitement with stripping down, making plans, ordering parts, it's a real buzz and quite exciting. Then comes the reality that you've got to put the work in to turn your plans into the bike you're trying to create. There is a seemingly endless period of cleaning, sorting, organising, prepping, priming, plating, fixing, grinding, welding, filling and modifying. I would wager that 90% of the 'Unfinshed Projects' you see advertised are somewhere in the midst of this no mans land stage. It's seemingly endless to the uninitiated. If you're made of stronger stuff you know that it's just the drudge that you have to get through before the good stuff starts to happen.

Paul popped over last week to be greeted with what can only be described as a sea of primed parts, nothing shiny or lovely looking and me telling him that we're on the cusp of shiny goodness. He looked a little deflated. I soldiered on undaunted!

That's just about where we are now, finished components going back together, the box full of new parts in bags being opened and the assembly process beginning.

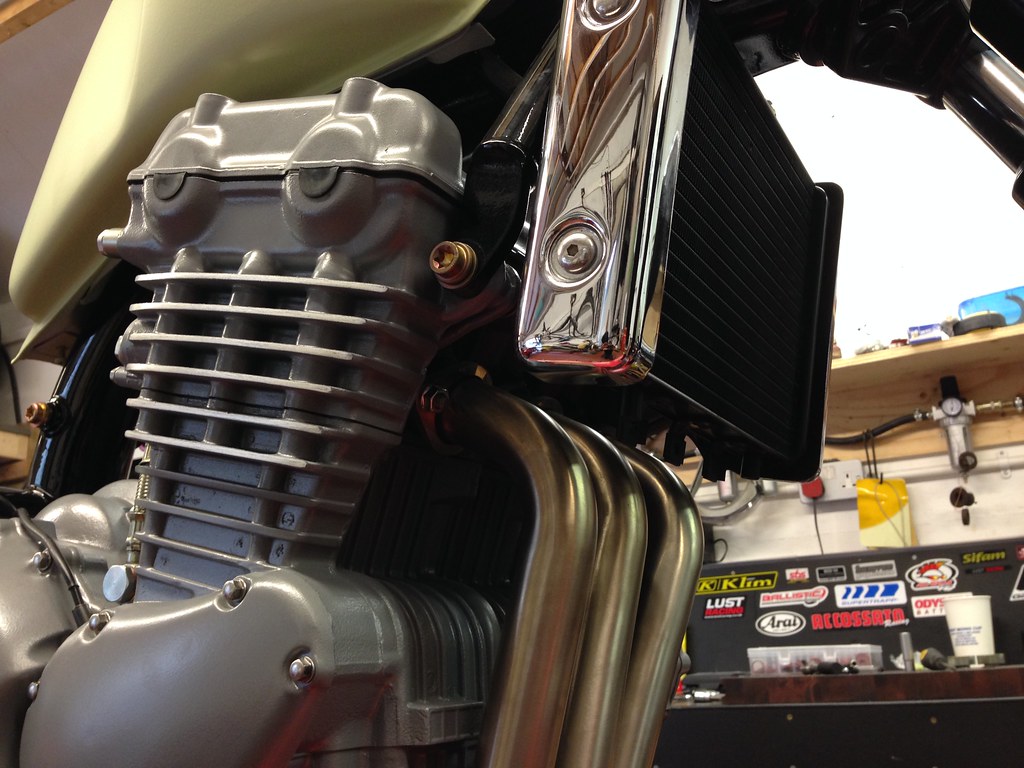

This is where is starts to look like a bike again! ........... This is where we see a smile on Paul's face again ......

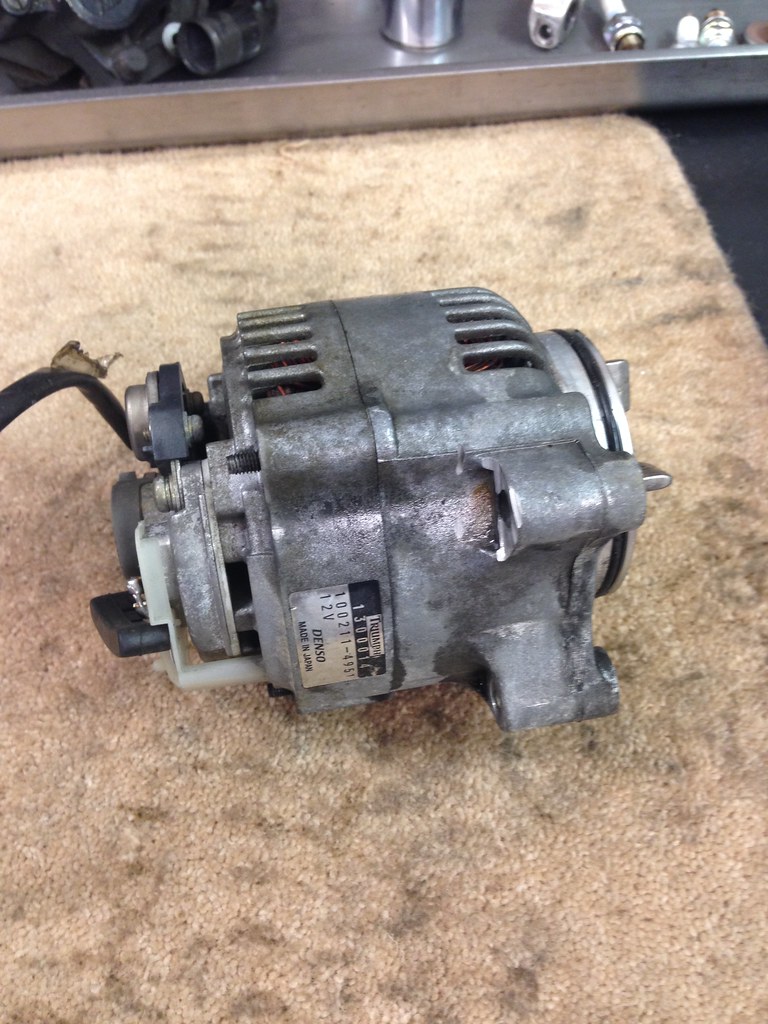

I'll let the photos do the talking ...

The original tank is being retained although it's not going to have the large chrome badges which come as standard. I'll cover the colour scheme later in the thread, for now it's just a case of prepping for paint.

First off, fill the badge fixing holes ...

Then, after 1x coat of 2k primer and 2x coats of high build primer ...

The top yoke originally had a cast flange on the front to which the original clock binnacle bracket and ignition barrel were fixed to. These have been removed to give a clean simple look. The rest of the recess left where the ignition barrel was has been slightly modified and is now home to the very simple speedo.

I fabricated a speedo mount, once I've finished fettling it I'll paint it black.

One last look before I turn the lights out ........