- Joined

- Mar 24, 2017

- Messages

- 21,697

- Reaction score

- 582

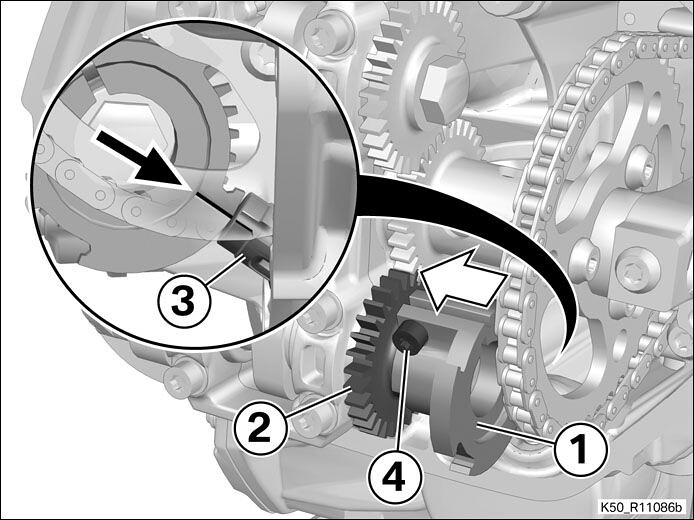

Done mine this morning. Both sides were a smidgeon out of alignment so I corrected them for the practice.

I had to use a small 1/4” drive socket to apply enough torque to the chain tensior because of my arthritic hands but apart from that it was fairly straightforward.

I note my TDC tool isn’t marked A / B on the ends and I’m ashamed to say I used the 6mm end for the first cylinder so had to do it again

Well done for having a go though, I'll be doing mine fairly soon.

Just waiting for SnapOn to send me the 16mm Torque Adapter ring