Thankfully only sometimes

A wee story of woe and eventually triumph :

:

So My Friend Fergy has a K1200RS 130bhp shaft driven high speed touring missile

In the highlands last year his alternator light came on and there was a rattle and he managed to nurse it back down to a garage where he ended up on a recovery truck to home

This is where I come in, he calls and asks do I think I could sort this I say I am busy doing other stuff and it'll block the ramp for a time while the bits are on the way but I'll give it a bash when it quietens down

To get at the alternator on a K1200RS 1997 -2005 you need to take it to a Gazillion bits :shock:

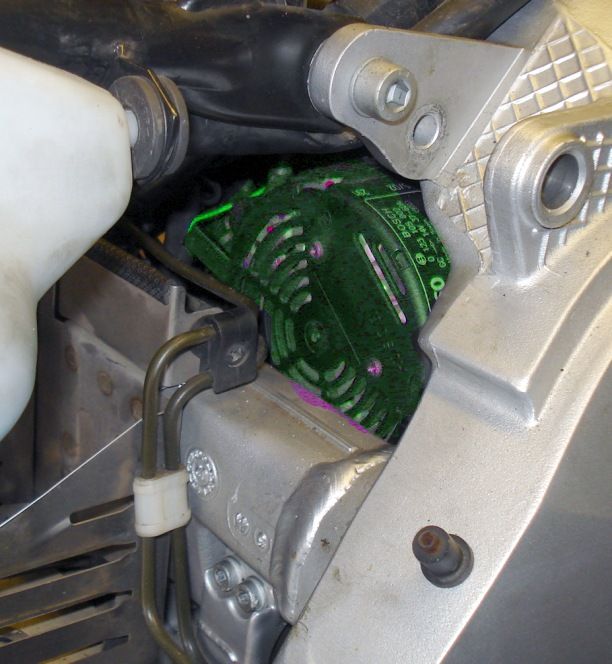

So one of these

becomes

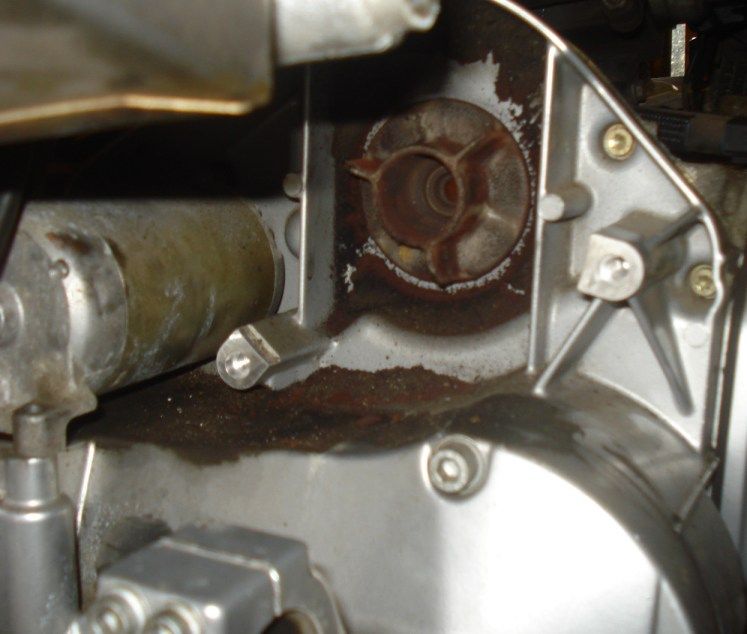

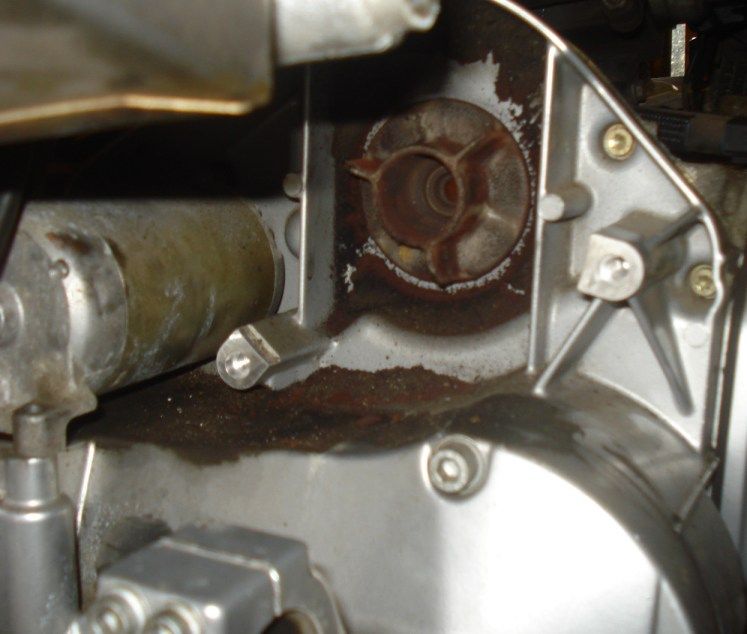

The rusty round bit is what you are looking to get at (bolt fell out already)

The offending item Which has left 9mm of thread in the auxiliary drive shaft

To get this far took 2 days! When they build them up there is not a "smidgeon" of grease to be seen or found anywhere on assembly, which is made worse when you find that some ARSE has already taken it apart before and decided that it NEEDS loctite where none is specified!

I will try and remember to take a pic of the swingarm pivot pins and their bushes, Lets just say It was for a moment or two it was touch and go that we were cutting the swingarm out!!

The in frame bush on the right side actually turned in the frame, it was so tight and had to be hammered out in the end and replaced with a good used one. The swingarm pins had to be treated to an old impact socket welded onto one side and successive runs of mig welding on the other side to get enough heat into them to get them out

When you get all the bits off that you need, including the nose fairing ( to undo the air intake scoop to take off the airbox)

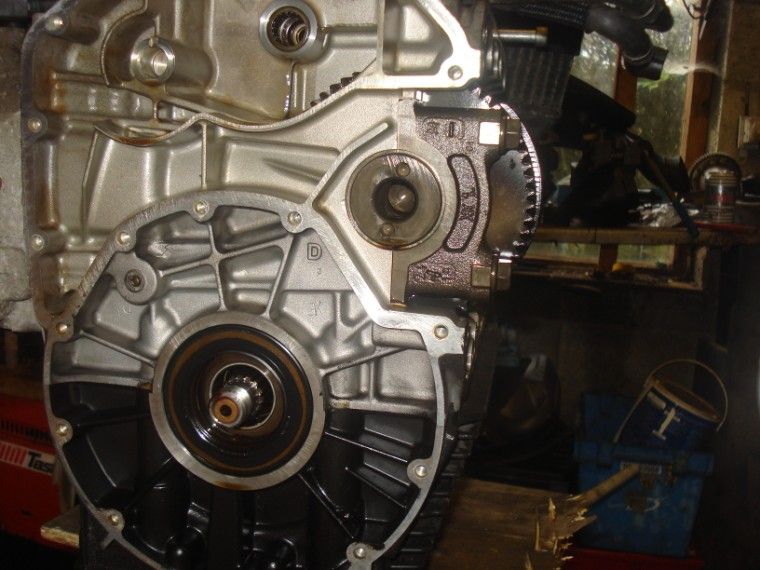

This is what a BMW K series "Brick" engine looks like when you are in this far!

That's the crank up high Normally hidden by a cover (Pic below) the water pump oil pump and the output to the flywheel being provided by a main auxiliary shaft that you can see sort of lower centre

and this is the smaller pile of parts from the clutch gearbox area that you have

Not forgetting the wheel, Drive, braking system, swingarm, shock, gearbox, etc etc

The shaft I am fixing drives off the crank and the starter works thru a one way clutch direct to the crank up at the top of the engine, all clean and ready to re assemble, Alternator goes top right Starter top left and the flywheel on the lower shaft with the new seal fitted

Once I realised that there was something very friggin tight inside and that it would have to be stripped again :

:

I hung my head and went and sat in a corner and opened a bottle of something refreshingly alcoholic and took a break and thought the process over ......

Yup I'd been careful VERY careful I'd checked part numbers I'd checked physical parts etc etc I'd cleaned everything so it was immaculately clean

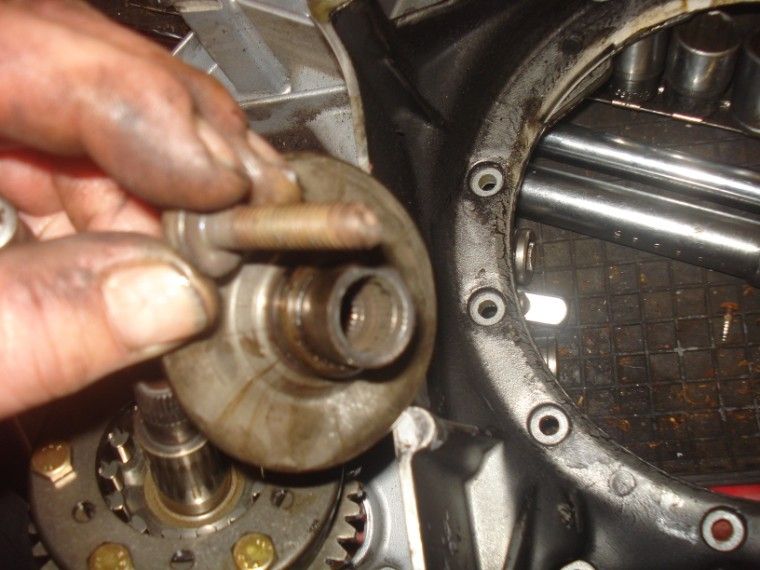

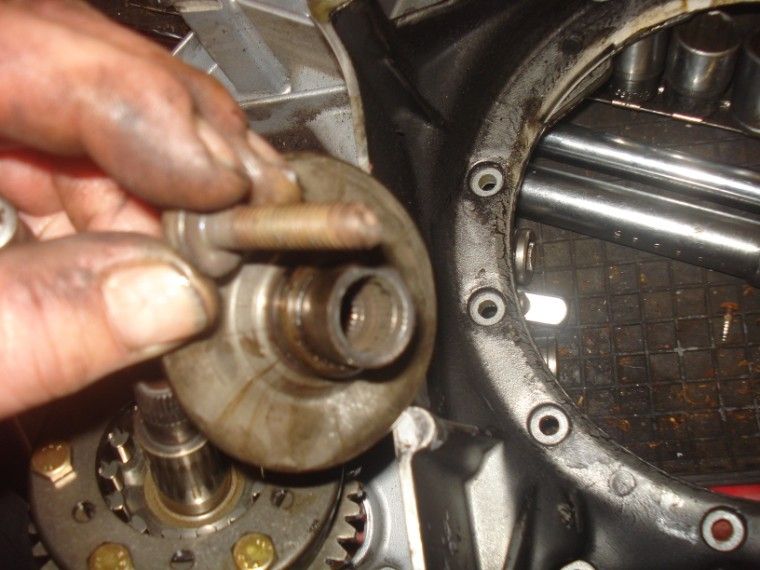

Look up the thread you will see the flywheel in the parts picture looking very manky and the auxiliary case in behind my hand here

The upside is that It was me that built it so grease where grease was needed and ONLY the two drops of loctite (Medium) where required

The bike came apart as it should

So I get it stripped back down, wheel, Final drive, swingarm, shock, gearbox, out etc etc etc

And I am Dumbfounded what's in the old parts box is what is fitted!

So I check the online microfiche and find Part 9

Link to Real OEM online Microfiche

Hmm I can;t remember any part 9 ?? Could it have broken up ??

So My Mate Granty arrives and he's asking how I am getting on and quite frankly I am am pretty much at a loss where part 9 is as I had stored like for like in the same box and the new parts to be fitted in with them ??

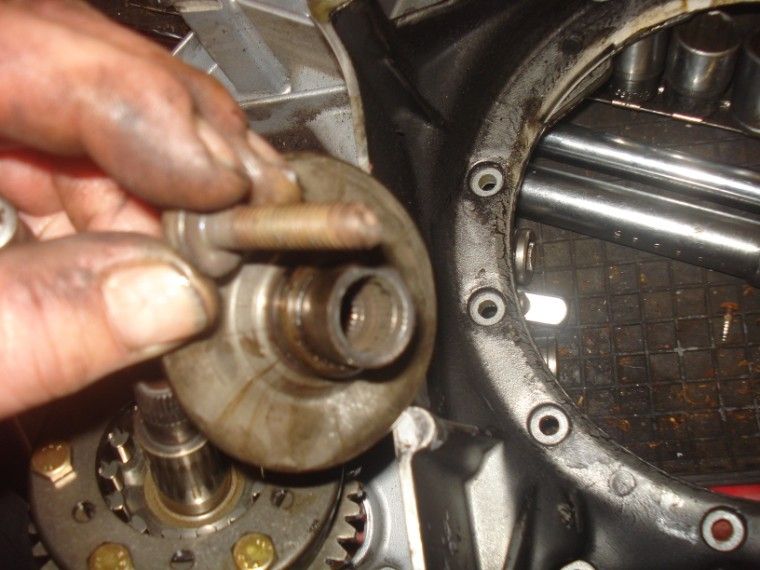

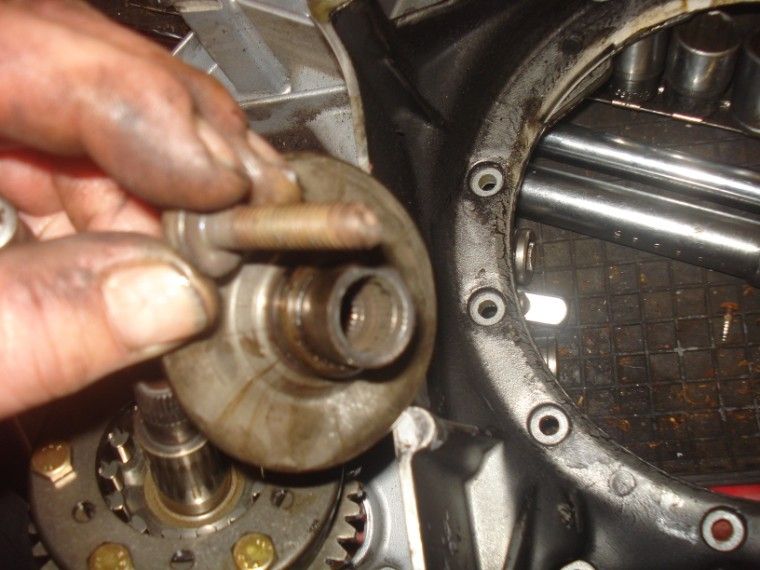

So I was showing Granty the drive dog and how the bolt holds it on etc etc

Look at the pictures and Say what you see??? This is the old drive dog retrieved from the old parts box

Looks okay doesn't it?

A wee story of woe and eventually triumph

:

: So My Friend Fergy has a K1200RS 130bhp shaft driven high speed touring missile

In the highlands last year his alternator light came on and there was a rattle and he managed to nurse it back down to a garage where he ended up on a recovery truck to home

This is where I come in, he calls and asks do I think I could sort this I say I am busy doing other stuff and it'll block the ramp for a time while the bits are on the way but I'll give it a bash when it quietens down

To get at the alternator on a K1200RS 1997 -2005 you need to take it to a Gazillion bits :shock:

So one of these

becomes

The rusty round bit is what you are looking to get at (bolt fell out already)

The offending item Which has left 9mm of thread in the auxiliary drive shaft

To get this far took 2 days! When they build them up there is not a "smidgeon" of grease to be seen or found anywhere on assembly, which is made worse when you find that some ARSE has already taken it apart before and decided that it NEEDS loctite where none is specified!

I will try and remember to take a pic of the swingarm pivot pins and their bushes, Lets just say It was for a moment or two it was touch and go that we were cutting the swingarm out!!

The in frame bush on the right side actually turned in the frame, it was so tight and had to be hammered out in the end and replaced with a good used one. The swingarm pins had to be treated to an old impact socket welded onto one side and successive runs of mig welding on the other side to get enough heat into them to get them out

When you get all the bits off that you need, including the nose fairing ( to undo the air intake scoop to take off the airbox)

This is what a BMW K series "Brick" engine looks like when you are in this far!

That's the crank up high Normally hidden by a cover (Pic below) the water pump oil pump and the output to the flywheel being provided by a main auxiliary shaft that you can see sort of lower centre

and this is the smaller pile of parts from the clutch gearbox area that you have

Not forgetting the wheel, Drive, braking system, swingarm, shock, gearbox, etc etc

The shaft I am fixing drives off the crank and the starter works thru a one way clutch direct to the crank up at the top of the engine, all clean and ready to re assemble, Alternator goes top right Starter top left and the flywheel on the lower shaft with the new seal fitted

Once I realised that there was something very friggin tight inside and that it would have to be stripped again

:

:I hung my head and went and sat in a corner and opened a bottle of something refreshingly alcoholic and took a break and thought the process over ......

Yup I'd been careful VERY careful I'd checked part numbers I'd checked physical parts etc etc I'd cleaned everything so it was immaculately clean

Look up the thread you will see the flywheel in the parts picture looking very manky and the auxiliary case in behind my hand here

The upside is that It was me that built it so grease where grease was needed and ONLY the two drops of loctite (Medium) where required

The bike came apart as it should

So I get it stripped back down, wheel, Final drive, swingarm, shock, gearbox, out etc etc etc

And I am Dumbfounded what's in the old parts box is what is fitted!

So I check the online microfiche and find Part 9

Link to Real OEM online Microfiche

Hmm I can;t remember any part 9 ?? Could it have broken up ??

So My Mate Granty arrives and he's asking how I am getting on and quite frankly I am am pretty much at a loss where part 9 is as I had stored like for like in the same box and the new parts to be fitted in with them ??

So I was showing Granty the drive dog and how the bolt holds it on etc etc

Look at the pictures and Say what you see??? This is the old drive dog retrieved from the old parts box

Looks okay doesn't it?