Yellow! Desert Sand to be precise, but yellow is the closest general description.

At 144,000 miles over the last seven and a half years the outside life was starting to take its toll...

The Ujs in the drive shaft had gone again; filled with water it was no surprise they had rusted a bit. I soon found the cause of that.

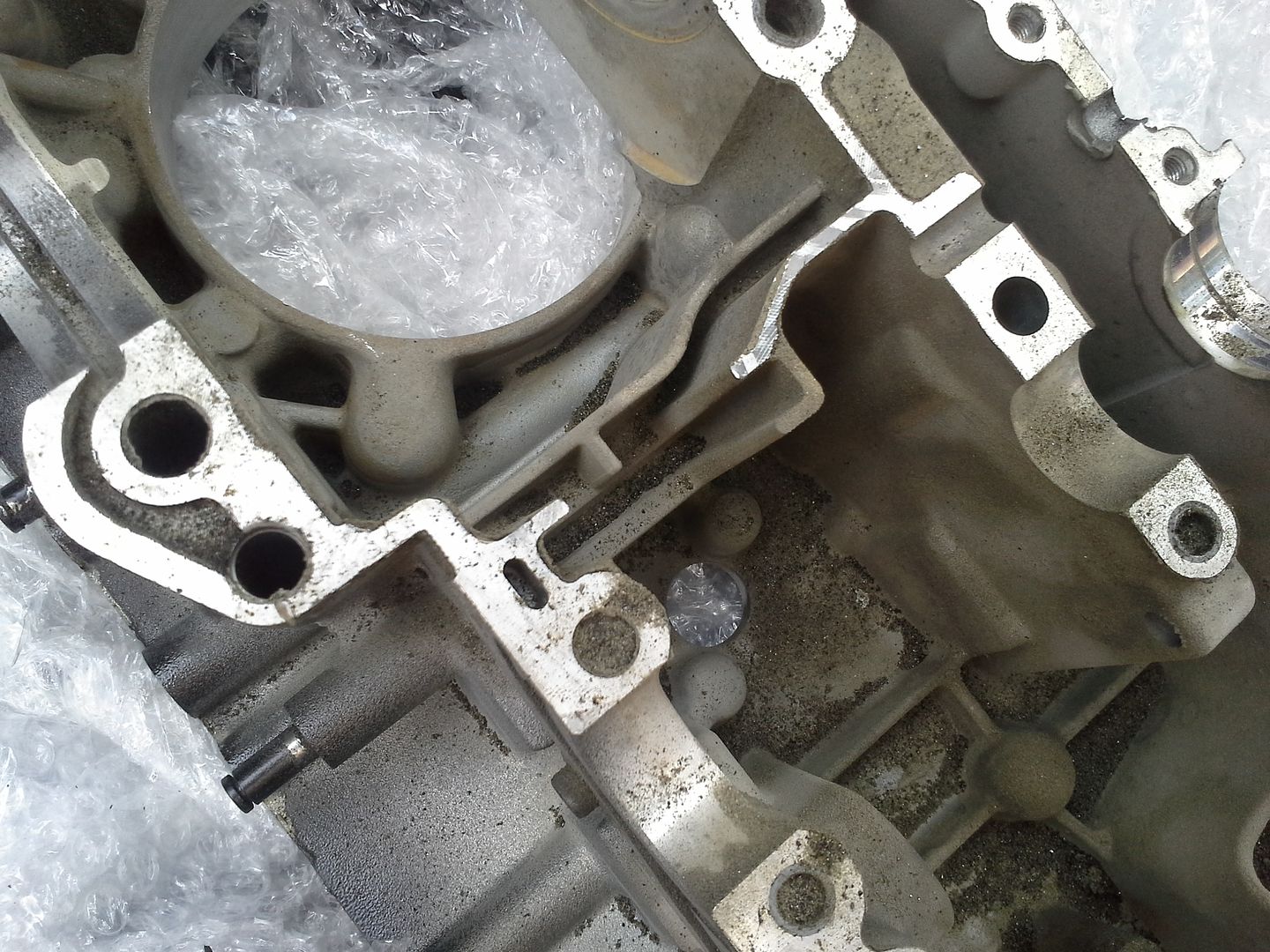

The drive shaft took bit longer than normal to sort out, the splines on the bevel drive end had also gone. So, whilst trying to find a suitable donor shaft to scavenge the plined yoke from, I decided to strip it down and have a bit of a clean up.

Nothing that a little lick of paint can't cure...

At 144,000 miles over the last seven and a half years the outside life was starting to take its toll...

The Ujs in the drive shaft had gone again; filled with water it was no surprise they had rusted a bit. I soon found the cause of that.

The drive shaft took bit longer than normal to sort out, the splines on the bevel drive end had also gone. So, whilst trying to find a suitable donor shaft to scavenge the plined yoke from, I decided to strip it down and have a bit of a clean up.

Nothing that a little lick of paint can't cure...