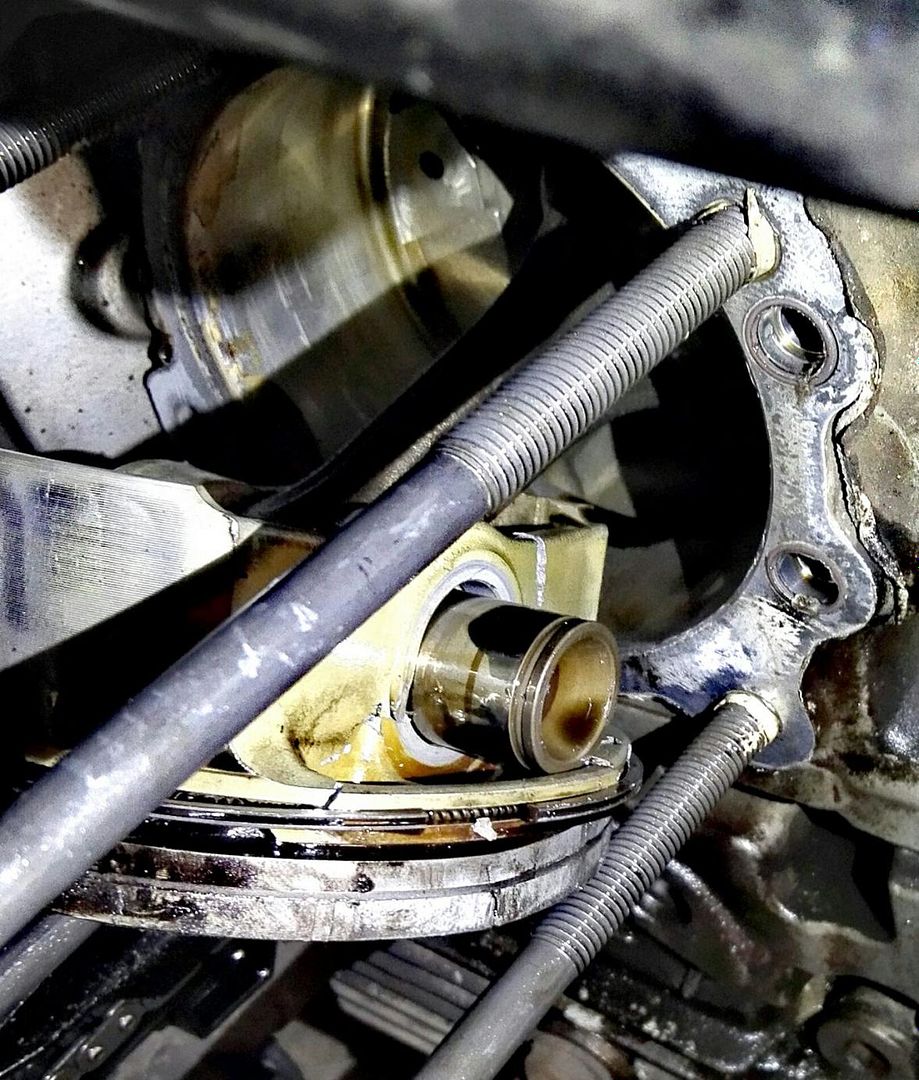

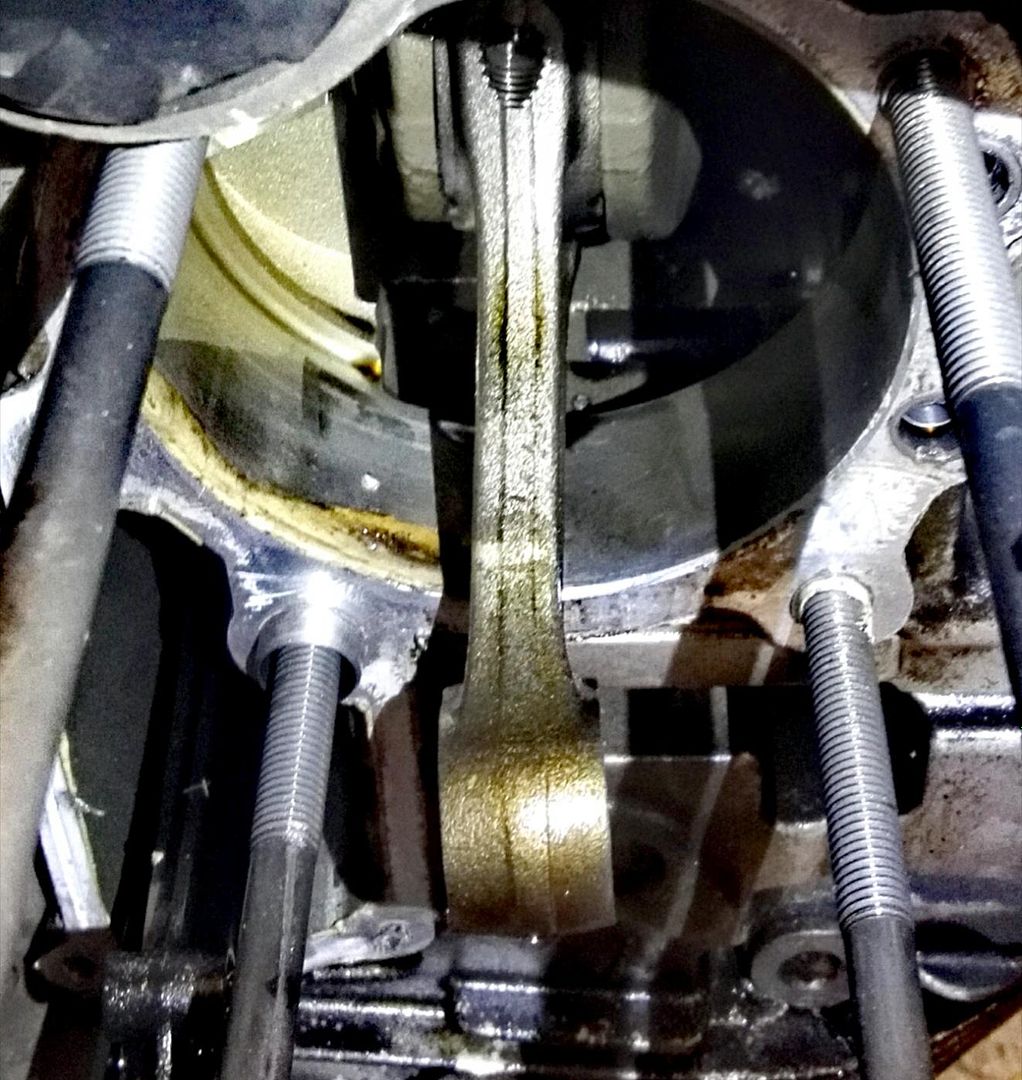

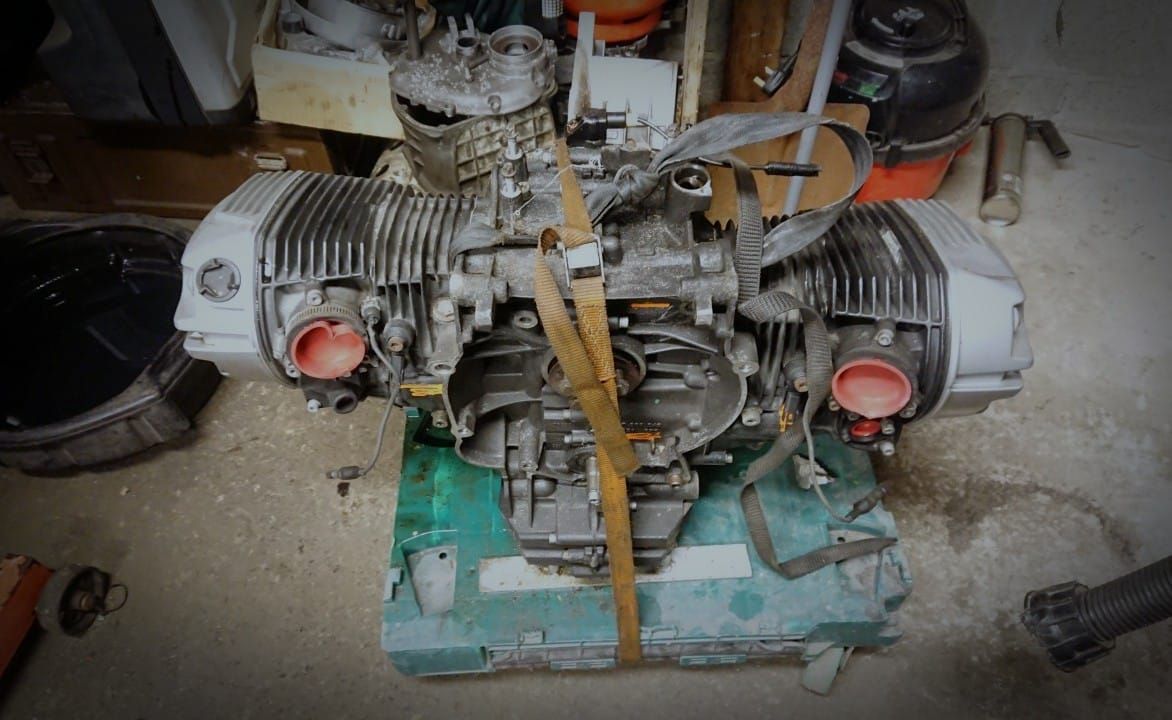

I need to remove the "knock sensor" off a head on my replacement engine for my 1200 (the one with the wire, just above and inboard of the throttle body)

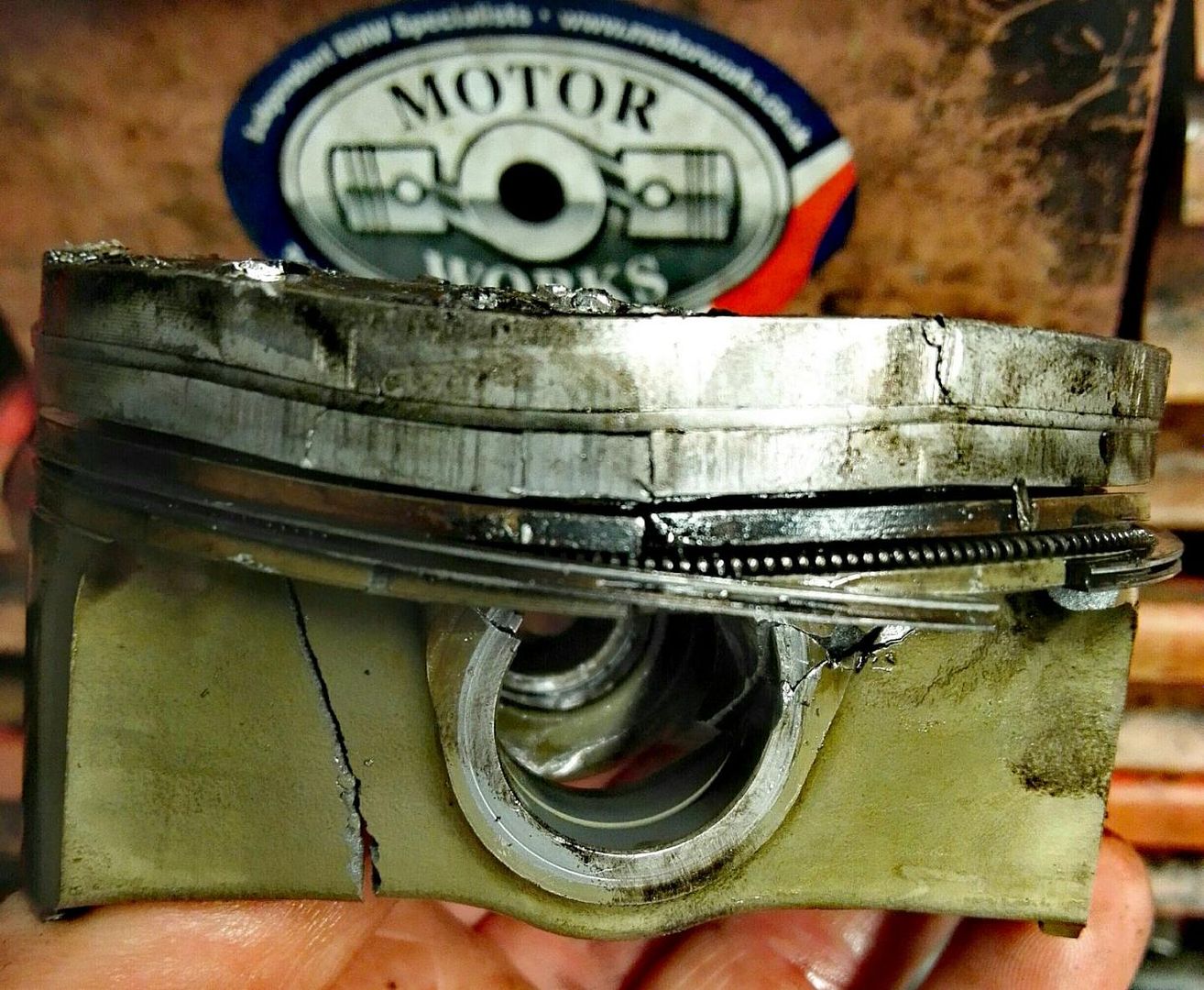

The cable is a bit squashed and I think I will use my ones off my old engine as I know they were good, Well they were good before it went bang

A socket obviously isn't going to work and I am not cutting a cable slot in one of my Grandads old britool deep cranked ringers so I thought I would ask for the special tool part number and start a search from that

Thanks in Advance

The cable is a bit squashed and I think I will use my ones off my old engine as I know they were good, Well they were good before it went bang

A socket obviously isn't going to work and I am not cutting a cable slot in one of my Grandads old britool deep cranked ringers so I thought I would ask for the special tool part number and start a search from that

Thanks in Advance